Understanding Tolerance Analysis: How Does Tolerance Analysis Affect OEM Products?

June 21, 2022 | By: Bobby Slocum

In manufacturing, tolerance analysis is a crucial step during the design and development process. It’s also critical during the hardware fit and performance troubleshooting phase. It’s a valuable tool to realize design intent and high-quality...

How Experienced Contract Manufacturers are ‘Problem Solvers’ for OEMs

December 21, 2021 | By: Hans Dittmar

“If your only tool is a hammer then every problem looks like a nail.” -- Abraham Maslow

What is a Cleanroom and Why Do You Need One?

December 6, 2021 | By: Macy Jenkins

What Is a Cleanroom?

3 Virtual Processes That Are Here To Stay

November 12, 2021 | By: Patrick Froh

Technology used to connect people virtually has exploded over the years and the COVID-19 pandemic accelerated that exponentially. Many companies had been hesitant to adopt virtual practices in the past, not seeing the benefit and preferred to do...

GMI Solutions' History in Logos

November 8, 2021 | By: Hans Dittmar

Softworks Development Corporation: The start of our journey. Every company has a story, and GMI is no different. Here is an overview of the path that brought us to become the world class outsourced assembly and test company we are today.

Design for Manufacturing Case Study: Hydraulic Lift

October 19, 2021 | By: Hans Dittmar

DfM: A Simple Solution. This particular product is extremely complex assembly work with cable routing and panel termination that takes place close to the cabinet bottom. This part of the assembly process alone takes multiple days of work which...

Shipping delays continue

August 11, 2021 | By: Macy Jenkins

About 90% of the worlds global trade is transported by ship, so when the worldwide pandemic, Covid-19 struck in the beginning of 2020, the continuous manufacturing flow of raw materials, parts, and consumer goods was put to a temporary stand still.

Supply Chain facing dramatic cost increases

May 19, 2021 | By: Jeff Holtebeck

Raw material, component and transit cost increases cause dramatic price spike. Memos announcing price increases have been arriving regularly from many of our component and materials suppliers, and at a historic cadence.

"Manufacturing What Matters" - What does it mean for you?

April 15, 2021 | By: Patrick Froh

Our motto is “Manufacturing What Matters”. It sounds meaningful to me. But what does it mean for you?Manufacturing what matters to me means to manufacture assemblies and turnkey products that are complex and critical to the end...

Chip Shortages Add To Supply Chain Beating

March 26, 2021 | By: Hans Dittmar

Everyone knew - early on - that as the economy rose, demand for durable goods and capital equipment would get back on track. The post-pandemic supply chain, however, keeps taking punches from a variety of unusual sources, including stuck ships...

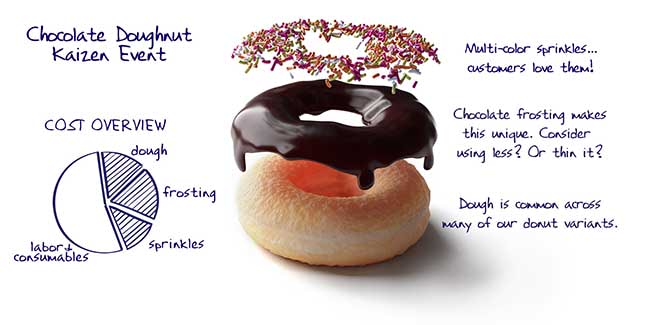

Value Engineering of Mature Products is Really a Thing

February 26, 2021 | By: Hans Dittmar

While there is a lot of discussion revolving around the differences between DfM, DfA and Value Engineering, they share many traits. Value Engineering is a process — originally developed and named by GE — that is considered by many to be applicable...