The Role of OEMs in Advancing Industry 4.0: Strategies and Benefits

July 22, 2024 | By: Miranda Campagna

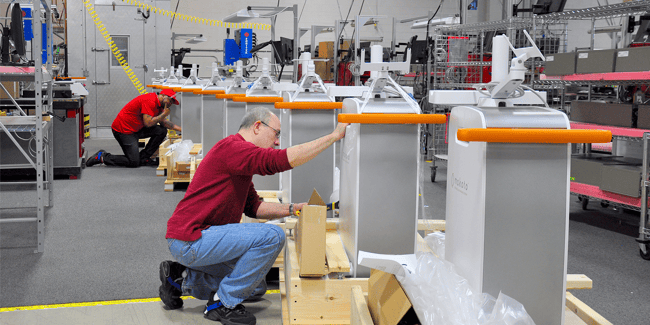

6 Benefits of Partnering with a Midwest Outsourced Assembly Manufacturer

July 11, 2024 | By: Miranda Campagna

In the ever-evolving world of manufacturing, Original Equipment Manufacturers (OEMs) face a multitude of challenges—from managing costs and maintaining quality to ensuring timely delivery and staying ahead of technological advancements. Partnering...

Understanding Persistent Organic Pollutants (POPs)

May 16, 2024 | By: Miranda Campagna

Persistent Organic Pollutants (POPs) are a group of toxic chemicals known for their longevity in the environment, ability to bioaccumulate, and potential to cause adverse health effects in humans and wildlife. They are resistant to...

Partnering with an ISO 13485 Facility: The GMI Solutions Advantage

February 29, 2024 | By: Miranda Campagna

In the rapidly evolving world of medical devices and equipment, the demand for high-quality, reliable, and regulatory-compliant manufacturing is more critical than ever. At GMI Solutions, we pride ourselves on not just meeting but exceeding these...

Why Partnering with an FDA-Registered Company is Key to Your Success

December 19, 2023 | By: Miranda Campagna

In the complex arena of medical device manufacturing, the U.S. Food and Drug Administration (FDA) plays a pivotal role in ensuring the safety and effectiveness of medical products. Navigating the FDA approval process is a critical, multifaceted...

Understanding the Crucial Role of Real-Life Scenario Testing

December 12, 2023 | By: Miranda Campagna

The Key to Excellence: GMI Solutions’ Rigorous Testing Process

Reshoring Realities: Navigating through the Opportunities and Challenges

December 8, 2023 | By: Patrick Froh

Riding the Reshoring Wave: Insights, Strategies, and Navigating Future Paths

Build Transfers: 12 Things Contract Manufacturers Need from OEMs

November 17, 2023 | By: Hans Dittmar

Navigating the Shift to Contract Manufacturing: A Strategic Guide for OEMs In an increasingly competitive global marketplace, Original Equipment Manufacturers (OEMs) are constantly seeking ways to balance cost and quality. A growing trend among...

The Future Impact of AI in Manufacturing

October 25, 2023 | By: Hans Dittmar

Manufacturing is at the cusp of a transformative era. As the integration of AI continues, its implications will permeate deeper into the production realm, leading to profound changes in how we conceptualize, produce, and distribute goods.

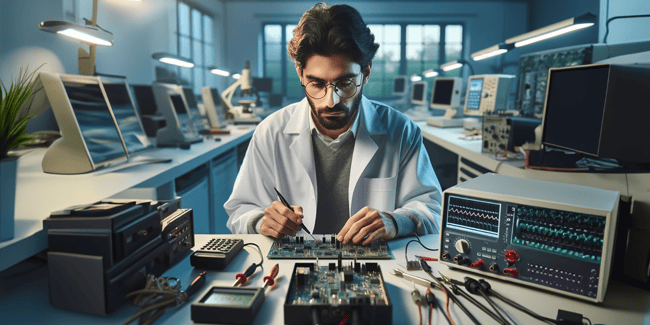

The Global Chip War: Implications for Manufacturing in the Future

July 31, 2023 | By: Hans Dittmar

July 31, 2023 The technology war between China and the United States continues, with recent developments signaling an escalation in trade tensions between the two economic giants. China's decision to impose export restrictions on critical raw...

How To Prepare Your Product For UKCA (UK Conformity Assessed)

March 30, 2023 | By: Hans Dittmar

The UKCA (UK Conformity Assessed) marking requires conformity with applicable UK regulations, which replaced the EU's CE mark in Great Britain following Brexit. This will have an impact on many products sold in the UK.

Are You Ready For "Made In China 2025"?

March 21, 2023 | By: Hans Dittmar

China's "Made in China 2025" directive is ramping up pressure on many multinational corporations - especially those with a large revenue footprint. This also means that many products sold into China will face challenges.