At GMI Solutions, we work to handle the complexities of the assembly process, giving OEMs the ability to focus on what they do best. Our professionals can manufacture everything from subassemblies to comprehensive turnkey solutions. In doing so, we fully customize our services for OEMs to give them precisely what they need at every turn throughout assembly, test and final logistics. Additionally, we work with OEMs in a range of critical industries, with past and current partners in sectors such as automation and controls, life sciences, healthcare, and oncology, among others.

Find out what sets our solutions apart and why we're the ideal go-to partner for contract assembly and sub-assembly services.

OEMs face multiple potential challenges when it comes to manufacturing, including the pressure to innovate, the need to shorten the time to market, and maintaining cost-effective operations. To overcome these and other challenges in this industry, GMI Solutions is here with a long history as a partner in OEM-focused assembly solutions that deliver results.

The following are some of the primary advantages of working with GMI Solutions:

We offer several solutions for our OEM customers based on their specific needs. We have deep expertise in complex electromechanical assembly. From intricate wiring to rigorous testing, we prioritize precision and reliability, ensuring your electromechanical products meet the highest standards. Our expertise extends to the integration of different types of embedded systems and software within each electrochemical assembly.

We also offer sub-assembly services, efficiently combining components to streamline manufacturing and accelerate the development of final products.

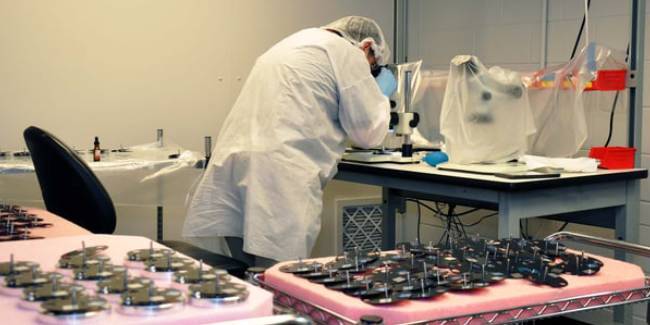

Our manufacturing solutions include ISO 13485-based capital equipment assembly, where we maintain the necessary assembly environment for sensitive assemblies using our Class 10,000 cleanroom.

Some of our other solutions include:

When project timelines and budgets are tight, OEMs often consider assembly-level testing a “nice to have” instead of a “need to have.” The peace ...

When it comes to successfully bringing a product to market, timing and collaboration are everything. For Original Equipment Manufacturers (OEMs), ...

In the ever-evolving world of manufacturing, Original Equipment Manufacturers (OEMs) face a multitude of challenges—from managing costs and ...

If you’re looking to outsource assembly services and free up time to focus on core aspects of your business, turn to the team here at GMI Solutions. We work to understand each partner's needs and develop a fully customized solution that truly works for you. We’ll offer the support you need and high-quality end results with comprehensive design, development, assembly, testing, and validation, covering all aspects of the assembly process.

Contact us today by filling out our contact form below, and we'll be in touch shortly to discuss your complete project needs!

GMI Solutions America

10202 North Enterprise Drive

Mequon, WI 53092 USA

(262) 242-8800

contact@gmisolutions.com

2025 © GMI Solutions. All Rights Reserved. | Terms of Use | Privacy Policy