Strategies to Mitigate the Risk of New Tariffs in the United States

December 17, 2024 | By: Patrick Froh

As global trade policies continue to shift, U.S. businesses are increasingly exposed to the risks of new tariffs. These can disrupt supply chains, inflate costs, and challenge competitiveness. However, with proactive strategies and the right...

5 Ways Flexible Outsourced Assembly Manufacturing Adds Value to High-Mix/Low to Mid-Volume Projects

December 12, 2024 | By: Patrick Froh

OEMs producing high-mix, low-to-mid-volume products face unique challenges, from adapting to fluctuating demand to maintaining cost efficiency. Flexible manufacturing offers a strategic advantage, ensuring seamless transitions, reduced costs,...

Navigating Global Risks: Why Regional Supply & Manufacturing is Crucial for OEMs

November 26, 2024 | By: Patrick Froh

The global supply chain landscape has become increasingly complex and volatile. From natural disasters to geopolitical tensions, unexpected global risks continue to challenge the stability and predictability of supply networks. This has made one...

Unleashing Value: The Power of Value Engineering in Product Design

November 20, 2024 | By: Don Rysdyk

During World War II, General Electric (GE) faced significant challenges—shortages of labor, raw materials, and essential components. As GE engineers searched for alternatives to replace these scarce resources, they made an unexpected discovery: the...

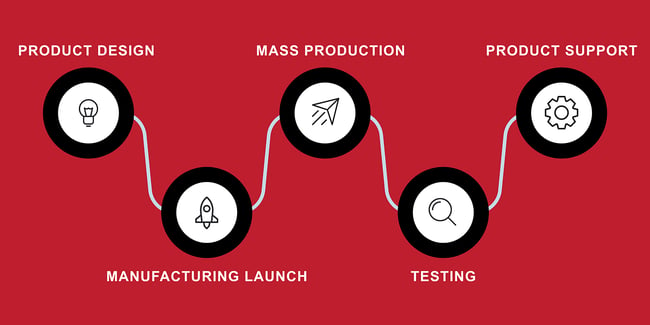

Why OEMs Choose GMI Solutions for Seamless End-to-End Program Management

November 13, 2024 | By: Patrick Froh

Outsourcing assembly work isn’t just about finding the lowest bidder or the quickest turnaround. It’s about partnering with a team that can fully manage the development process, from initial concepts to final products, and beyond. This level of...

The Importance of Supporting Long Life Computer Solutions for OEMs

October 24, 2024 | By: Hans Dittmar

In today’s rapidly evolving technology landscape, Original Equipment Manufacturers (OEMs) are tasked with developing a diverse range of products, each with unique complexities. For OEMs that produce electromechanical computers, whether it’s a...

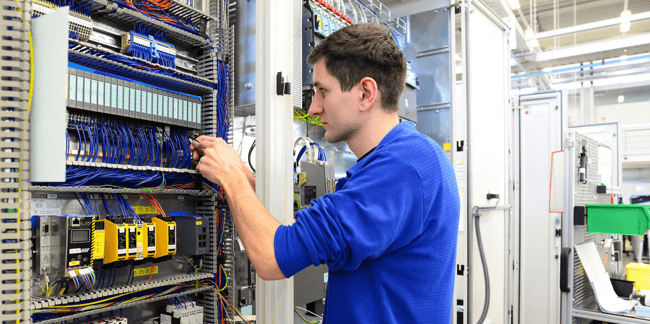

The Advantages of Involving Your Outsourced Assembly & Manufacturing Partners Early in Product Design

October 21, 2024 | By: Hans Dittmar

When it comes to successfully bringing a product to market, timing and collaboration are everything. For Original Equipment Manufacturers (OEMs), getting your manufacturing partner involved early in the design process can be the difference between...

How to Measure and Reduce Total Cost of Ownership (TCO) with Make vs. Buy

September 27, 2024 | By: Hans Dittmar

Accurately measuring and reducing the Total Cost of Ownership (TCO) is crucial for manufacturers. This guide explains how to identify and minimize these costs through strategic outsourcing. Partnering with experts like GMI Solutions can help OEMs...

Elevating Standards with High-Voltage Manufacturing Capabilities at GMI Solutions

September 19, 2024 | By: Hans Dittmar

In the demanding landscape of modern manufacturing, where precision and safety are paramount, GMI Solutions is leading the charge with its state-of-the-art high-voltage testing capabilities. As industries worldwide increasingly rely on...

Keeping Our Promise: How GMI Solutions Ensures OEMs Quality and Reliability

August 30, 2024 | By: Miranda Campagna