OEM Reshoring Guide: Bringing Manufacturing Back to the USA

October 20, 2025 | By: Hans Dittmar

For decades, outsourcing production overseas seemed like the obvious choice for many OEMs because of benefits like lower labor costs and established manufacturing infrastructure. But the COVID-19 pandemic, tariffs, geopolitical conflicts, and rising...

Navigating Supply Chain Challenges: Key Concepts of the GMI Mitigation Strategies

April 4, 2025 | By: Patrick Froh

Navigating Supply Chain Challenges: Key Concepts from the GMI Mitigation Strategies In today's rapidly changing global market, businesses must adapt to supply chain disruptions and uncertainties.

5 Really Big Reasons for the Recent Interest in Reshoring to the United States

March 26, 2025 | By: Hans Dittmar

The Essential Needs of ESD Safety When Handling Electronic Assemblies

March 20, 2025 | By: Patrick Froh

In the manufacturing industry, safeguarding electronic components from electrostatic discharge (ESD) is not just a recommendation; it's a necessity. Neglecting ESD safety can lead to product failures, costly recalls, and compromised customer trust.

How TSMC and Intel's JV Could Revolutionize Chip Supply Chains

March 13, 2025 | By: Patrick Froh

The potential joint venture between TSMC and Intel could mark a transformative era for the semiconductor industry, significantly enhancing chip supply chains and stabilizing prices.

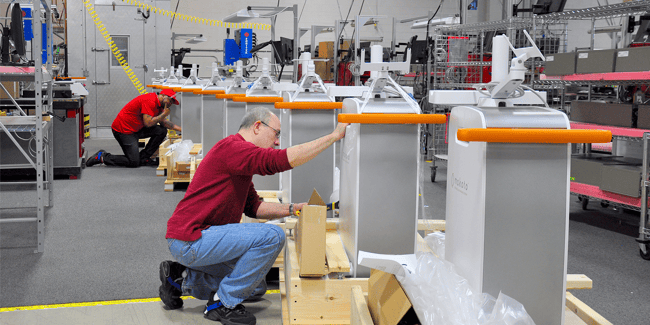

GMI Solutions: Excellence in Cart Integration and Assembly

March 5, 2025 | By: Patrick Froh

Unlocking Precision: GMI Solutions' Expertise in Cart Integration and Assembly

The Impact of Apple's $500 Billion Investment on US Manufacturing

February 25, 2025 | By: Patrick Froh

Apple's $500 Billion US Manufacturing Expansion: A Boost for American Industry

Navigating the Storm: How Global Trade Tensions Will Impact Your Supply Chain

February 12, 2025 | By: Patrick Froh

In the ever-evolving landscape of global trade, the recent escalation in U.S.-China trade tensions has sent ripples through the supply chain. With retaliatory tariffs affecting a staggering $23.6 billion in trade, businesses are bracing for impact.

Case Study: Data Input Keyboard for Critical-Use Medical Device

February 3, 2025 | By: Hans Dittmar

In the highly regulated and precision-driven world of medical device manufacturing, every detail matters in critical-use applications. Any missteps or malfunctions have consequences, ranging from opening the door to competitors’ solutions to dire...

How Tariff Wars Impact Healthcare Equipment Manufacturing: 8 Major Risks and Solutions

January 14, 2025 | By: Patrick Froh

Tariff wars between the United States and our major trading partners pose significant challenges for Original Equipment Manufacturers (OEMs), particularly in healthcare manufacturing. For outsourced assembly and contract manufacturers, tariffs...

2025 Global Supply Chains: What to Watch For...

January 10, 2025 | By: Patrick Froh

As we navigate 2025, global supply chains are poised to encounter a complex array of challenges and opportunities. Building upon insights from recent analyses, here are some key areas supply chain professionals should monitor:

Strategies to Mitigate the Risk of New Tariffs in the United States

December 17, 2024 | By: Patrick Froh

As global trade policies continue to shift, U.S. businesses are increasingly exposed to the risks of new tariffs. These can disrupt supply chains, inflate costs, and challenge competitiveness. However, with proactive strategies and the right...